Charging or changing

When some battery-powered household appliance stops working, for example, a flashlight or a TV remote control, the normal user is not spending a time thinking about what to do and changes the battery immediately. This usually takes a few minutes at home. The question arises, why not do the same with an electric car? Seems that it is easy – change the battery and go drive while the previous one is charging. But is it really so easy? Let’s figure out.

There is a point of view that the future is not for charging stations, as such, but for so-called automatic battery changing centers (BCC) where spent discharged batteries can be replaced with charged ones with the robot assistance. The driver pays for the amount of energy received, the price of which already includes payment for BCC services, storage, transportation, etc. After the car leaves the BCC, the robot puts the removed battery on charge. After the battery is charged, it enters the battery exchange fund and is ready for distribution to a new client.

First of all, the obvious advantages of this method of charging come to mind.

First, there is always a high rate of energy production (in this particular case, there is no need to talk about the actual charging). The process of replacing batteries takes several minutes, which is equivalent to the time spent on a regular refueling of a car with an internal combustion engine.

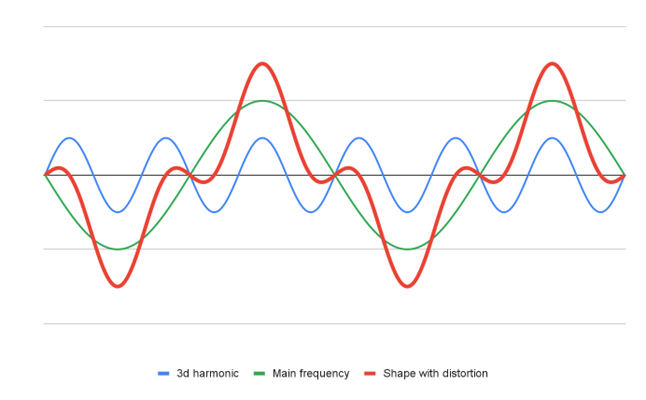

Second, with this method, there is no need for high-power devices that use the so-called “fast charging”. It is known that fast charging can only be really fast within a certain range of battery charge (usually from 20 to 80%). Slow charging, on the other hand, charges the battery up to 100% with a slight speed deviation. Thus, each battery from the driver’s point of view will be charged “quickly” to a full charge.

Third, fast charging is an additional cause of battery wear, reducing its life. Slow charging, which will be used at replacement centers, will increase battery life, the number of charge cycles. The effect can be felt with a large number of electric vehicles using such centers (BCC).

Four, if everyone uses battery replacement instead of charging it, then the battery does not need to be cooled during charging, which will greatly simplify the design of the battery, and therefore reduce its cost.

Five, with all above, as a backup option, of course, there should be a converter on board the car, but its cost, weight and dimensions can be minimized, since it will not be used often. More often than not, the battery will simply be replaced. It’s like a kind of spare tire.

It would seem that everything is logical and replacing the battery as a first approximation looks quite attractive. But in the second approximation, everything looks a little more complicated.

One of the downsides of changing batteries is the owner’s sense of ownership of an electric car. The battery is perceived by almost all owners as part of the car, indistinguishable from the wheels, engine, seats, etc. Replacing the so-called “own” battery, which the owner cherished and kept in good condition from the very purchase of the car, with some other, who knows who previously owned, causes, if not psychological trauma, then causes significant discomfort to the owner. Therefore, few people agree to replace the battery, even if they are guaranteed a certain number of kilowatt-hours during this procedure.

Fears arise from the habit of being sure that the end point of the travelling is reachable. After all, if the number of kilowatt-hours is insufficient to achieve the intended location, then this will be associated with certain problems, in the easiest case, connected with the loss of time for recharging somewhere along the way. If we are talking about a long trip, then this is critical. But even when traveling in the city, you don’t want to once again be distracted by charging the car.

Problems may also arise for the charging side, the operator of the BCC. He cannot be sure that he will get a normal battery. If this happens, then the degraded battery may not receive as much energy as the operator spends on charging it. Part of the energy will go into heat, since it is well-known that in lithium-ion batteries, with an increase in the degree of wear, the intensity of heat release increases during charging. The amount of energy that goes into heat can be quite significant, just remember how the battery behaves on an old smartphone. In the case of a car traction battery, the currents are completely different and the heating is also much stronger. And there are not many who want to heat the atmosphere at their own expense. By the way, this is another argument that speaks against battery replacement as a way to deliver energy to an electric car.

The fact is that modern batteries have their own cooling system with temperature sensors, coolant and other devices that help monitor the temperature and ensure timely cooling of the battery both during charging and during operation. These additional devices are of various types, not always included in the design of the battery itself. This circumstance creates some inconvenience for the operator involved in replacing the battery. These are additional operations that may not be easily and cheaply automated.

Well, besides, the guaranteed amount of energy stored in the battery may differ from what the owner expected. Perhaps his battery capacity is significantly higher than he will be offered to replace. The way out of this situation can be the unification of batteries, bringing them to a single row. But in this case, car manufacturers will not be able to highlight their competitive advantages and there is a risk that all the variety of cars on the market will turn into one model called an “electric car” or something similar. The likelihood that car manufacturers will take such a step is very small.

Another circumstance should be taken into account when discussing the battery replacement procedure. What should we do with the remaining battery charge when it is returned and exchanged. Will the driver be paid for this? For example, if you know that you have a long road ahead, and you only have 70% battery power and you know that this will not be enough. Suppose you are given a fully charged battery at the charging center and there is enough energy left to get to your final destination. How much should I pay for such an operation? How to measure the remaining charge in the battery? There are more questions than answers here.

Let’s move on. Replacing the battery is, after all, a mechanical operation. Moreover, it is necessary to operate with a rather large weight. Now, for example, an 80 kWh battery weighs around 500 kg, and a 120 kWh battery already weighs more than 700 kg. Such scales require equipment of great strength and corresponding power. With all this, it still must be accurate enough to position the manipulators relative to the machine. And if we also take into account the fact that the battery, as a rule, is located in the lower part of the car, then preliminary operations for cleaning the bottom of road dirt and drying are automatically added here. This together increases the complexity, energy intensity and cost of charging center equipment, and thus increases the cost of its services to users.

The place where it is possible to replace batteries (BCC) is a special infrastructure facility with an underground and above-ground part, with power supply, ventilation and other attributes of an industrial building. While the fast charging charging station is a stand-alone device resembling a household refrigerator in size and does not require special work when installed. And if we talk about an AC charging station, then its dimensions can generally be neglected. This affects the amount of investment required for the BCC. So, the cost of its services, which must ultimately be paid by the consumer.

Another argument against the idea of battery replacement is that the charging centers (BCC) will have to have a sufficient supply of batteries in order to smooth out the uneven demand for the service. It is not known in advance in which place and at what time the demand peak will occur. So, you need to be prepared for increased demand in one or more locations. And this will inevitably lead to a freezing of funds, increasing the already considerable investments of companies that have decided to become operators of BCC. In addition, practice shows that people will want to take a battery for replacement in one place, and take it in another. There will be a so-called “migration” of batteries. Transport will be needed to ensure more or less equal availability of replacement batteries between multiple locations. Again, this is an additional cost.

In the end, the charging process still remains, but when changing batteries, all sorts of mechanical operations are added to it.

Thus, it turns out, in principle, the replacement of batteries can be done. The only question is at what cost? It is the increase in the cost of this process compared to charging from the network, no matter fast or slow, that stops the decision in practice.

By the way, about practice.

The well-known Tesli company conducted an experiment to study the demand for a battery replacement service. According to the company’s statement, such a service turned out to be unclaimed in the market.

For interest, you can watch a video on YouTube, where Elon Musk changes the Tesla battery twice as fast as they fill it at a regular Audi A6 gas station. Tesla does it faster there, but there are questions, one of which is how many kilometers one Audi refueling will last and how much Tesla?

Video is by the link